Product Introduction

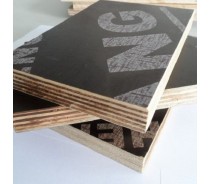

Brown film faced plywood is one kind of marine plywood which also called as phenolic plywood, shuttering plywood, concrete plywood, formply. It is one kind of waterproof layered plywood after hot press, sanding and film faced, which with single side brown film or two sides brown film.

Product Specification

|

Product name |

Brown film faced plywood |

|

Brand |

FORYOU |

|

Sizes (mm) |

12202440mm, 12502500mm, 915x1830mm, 12001800mm. Customized size are available. |

|

Thickness (mm) |

6, 8, 9, 10, 12, 13.5, 15, 16, 17, 18, 20, 21, 24, 27, 30 |

|

Film |

Brown film |

|

Core |

Combi core, poplar core, eucalyptus core, birch core, hardwood core, reused plywood finger joint core etc. |

|

Density |

520-720 kg/m3 (+/- 50 kg) depending on different core material |

|

Glue |

MR, WBP Melamine, WBP Phenolic |

|

Thickness tolerance |

+/-0.2mm, +/-0.5mm, +/-1mm |

|

Length or Width Tolerance |

+/_2mm |

|

Moisture Content |

10% (+/- 2%) |

|

No of plies |

From 3 layers to 21 layers depending on plywood thickness |

|

Edges treatment |

Waterproof paint spraying on the edge of the plywood |

|

Package of product |

Standard export pallet packing or loose packing |

|

Use time |

3-20 times depending on different core material and application conditions |

|

Certification |

CE ISO9001 FSC CARB |

|

Application |

Concrete formwork, outdoor construction, floors, etc. |

Product Features and Application

The surface of this film faced plywood is smooth, water resistant and corrosion resistant. It is very easy to demoulding and clean which is more conducive to the later construction. Sometimes, the surface of film faced plywood will be required to do anti-slip treatment. At this time, when producing film faced plywood, we will replace the steel plate according to the customer’s requirements, so that we can manufacture the anti slip film faced plywood with different patterns and effects.

Film faced Plywood can be cut to different sizes depending on construction needs. At the same time, It can be reused many times, which greatly saves construction costs. It is mainly used for concrete formwork when people build houses or bridges. Sometimes film faced plywood can also be used for floors of vehicle and, airline crates, shelves, etc.

Product Details

Quality Control

We have professional production team and quality inspection team which most of them already worked in the panel industry more than 10 years. We will check each sheet of plywood before package, including:thickness, length, width, moisture, bonding strength, surfaces, etc.

Packaging and Loading

1) Inner packing: Inside pallet is wrapped with a 0.20mm plastic bag and corners to protect the edges.

2) Outer packing: Pallets are covered with 2mm package plywood or carton and then steel tapes for strengthening.