QT10-15 automatic concrete pavement hollow block making machine price in new zealand sri lanka

Compared with traditional brick machine, automatic cement brick making machine can produce cement bricks without burning. It adopts the advanced technology, which the characteristics of compact structure, simple operation, low failure rate, stable performance and high productivity.

This is one large capacity type fully automatic concrete hollow block production line. It made up of host machine,stacker machine,hydraulic station plaform,PLC system,JS750 Mixer ,one set of mold,2 hydraulic trolleys . All of these need one 40 feet container to ship to your country.

1.Main Technical Specifications

|

Overall dimension: |

3500 ×2300 × 2930mm |

|

Pallet size |

1300×900×25mm |

|

Moulding area |

1196×880mm |

|

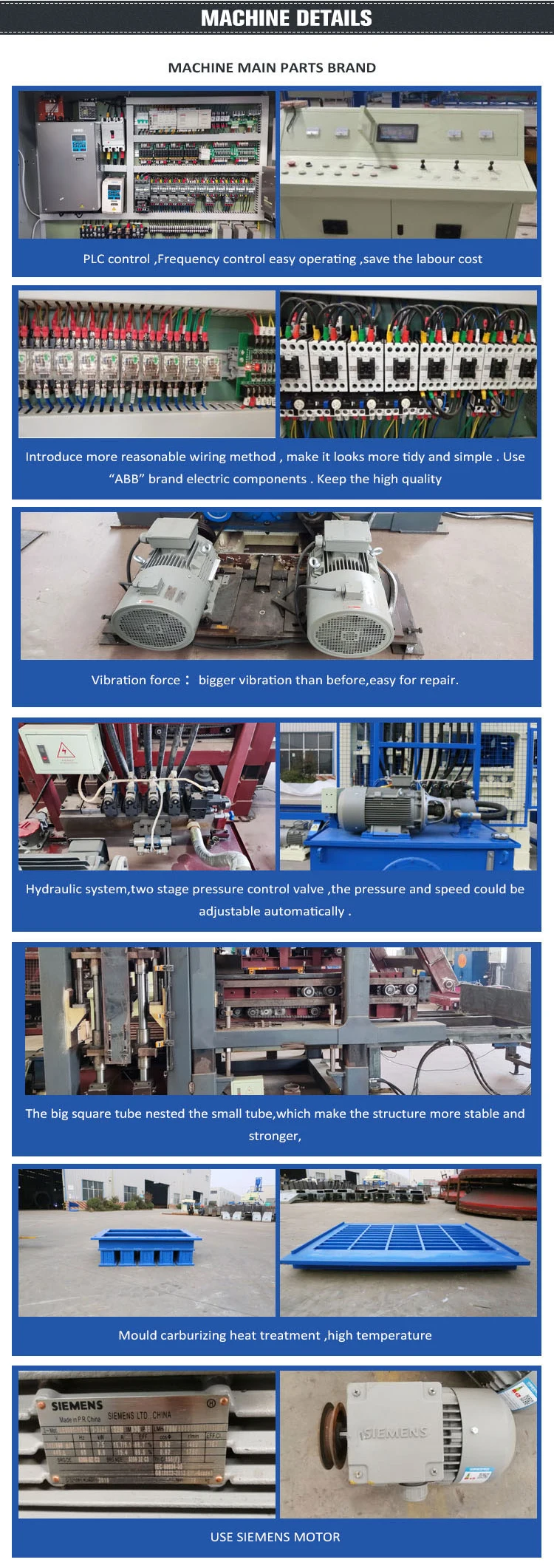

Vibration force |

90-110KN |

|

Workshop area |

300-350m2 |

|

Mixer model |

JS750 or JS1000 twin shaft mixer |

|

Technology |

Masa technology |

|

Block mould technology |

Heat treatment, Wire cutting |

|

Steel standard |

GB Q235 |

|

Moto brand |

SIEMENS or ABB or Chinese famous brand |

|

Welding |

Carbon dioxide welding |

2.Fully automatic concrete block machine production line included

|

1. cement silo |

2. 6m screw conveyor |

|

3. cement and water scale |

4. batching machine |

|

5.concrete mixer |

6. material hopper |

|

7.hydraulic station |

8.material conveyor belt |

|

9.pallet feeder |

10.block receiver |

|

11.PLC station |

12.concrete brick machine |

|

13.stacker |

14.forklift |

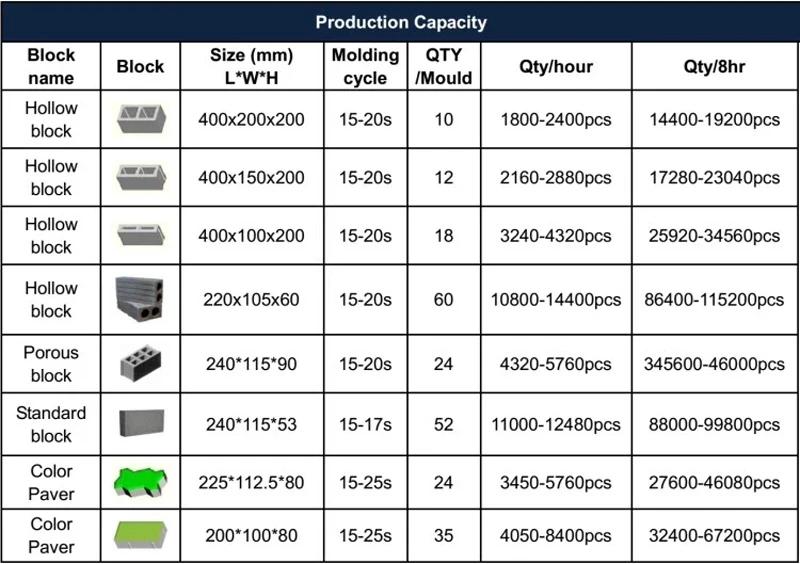

3.Theoretical capacity

This concrete brick machine has large capacity for many kinds of blocks. Suitable for big investment, and if you want make hollow block, color paver and curbstone together, also want big quantity one day, suggest you choose this type brick making machine for sale.

QT10-15 automatic production line needed data

1. Area: Workshop area: 150-200m2, all factory area 3000m2, the bigger, the better.

2. Workers : four or five

3. Ratio of raw material: cement 8%-10% sand 30%-40% stone:50%-60%,about cement :sand : stone is1:4:5.

4.Hollow block weight:(400*200*200) :17KG,(400*150*200):13.5KG,(400*100*200):10KG

5. Raw material consumption per day:160-170T

6. Water consumption per day:3%-5% of raw material

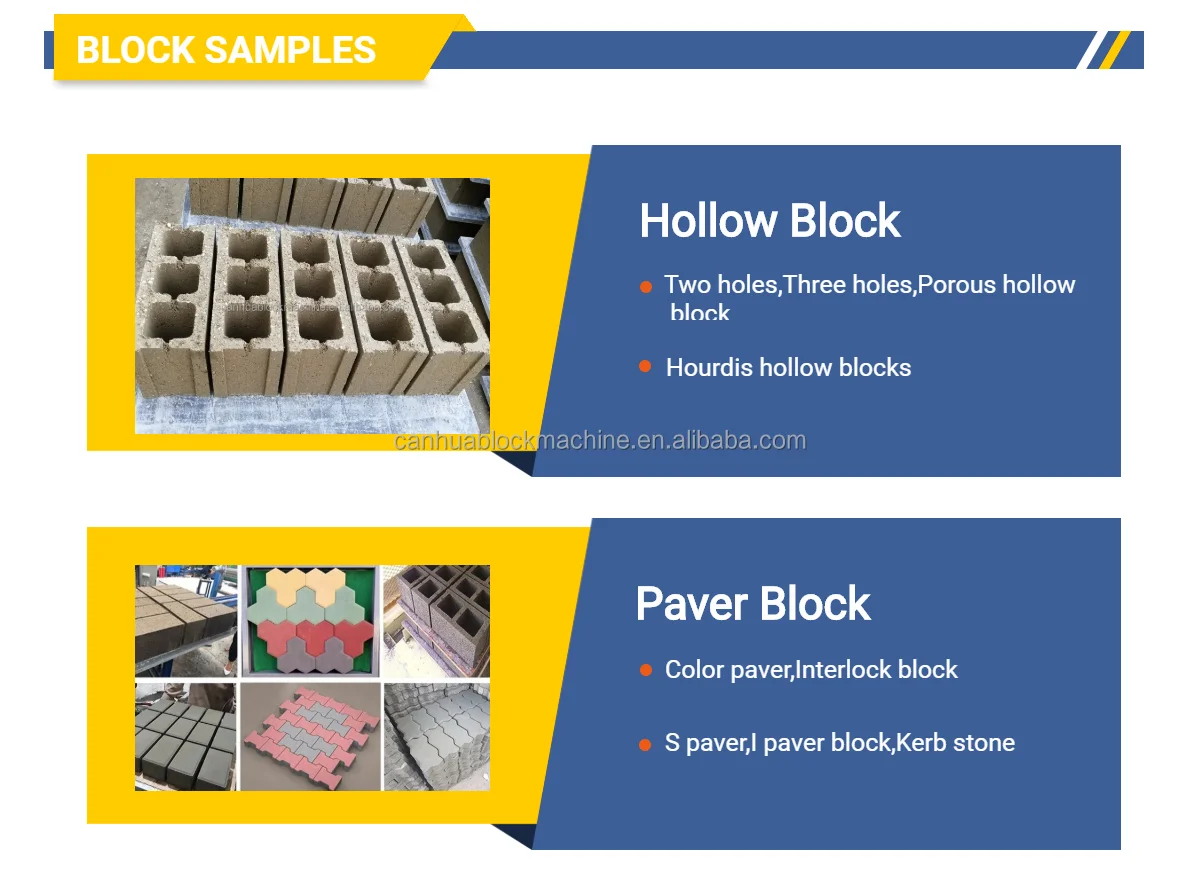

7. Blocks: can make all kinds of hollow and solid blocks, the pressure hollow blocks is about 8-10Mpa, solid is about 10-12Map. Can be widely used in low walls .

8.how to cure the bocks: in very hot area, about many hours can be stacked from the pallets, in the first 5-7days must spray water to cure, about 7 days can be sell. in usual area, about one day later can be stacked from pallets, in the first 5-7 days must spray water to cure. about 14 days can be sell.

According to the production concrete hollow block making machine output,It needs to match with JS750 Mixer machine.

Other accessory machines

The fully production line you may also need: Manual hydraulic trolley,3T forklift,1.5T wheel loader

If you need to make colorful paver blocks,you just need other three machines: one color feeding machine,one color material mixer JD350 type, one set 4m color material belt conveyor.

Processing project

For you can use our block machine much more reasonably, we afford you two kinds design production line for your choice:

1).Full line one set block machine system,one set concrete mixer system,one set batching system,and one set cement silo.

2).Full line two set block machine system, two set concrete mixer system,one set batching machine and cement silo.

You no need invest twice price to let your production line’s capacity add to double.

No matter which project you prefer, actually you can reclaim your cost less than one year.

1. The whole concrete interlocking block making machine production line equipment is mainly the full container sea shipping,

2. Block making machine for sale equipment finish manufacturing and testing, next to clean up, and then do another paint protection,

3. Before shipment to use plastic film winding, wrapped the entire cement brick machine in case of water or moisture,

4. Then load brick machines into the container by forklift.

5. During loading to tighten the machine with reinforcement ring in container, so as to avoid the damage by transport bumps on the hollow block making machine.

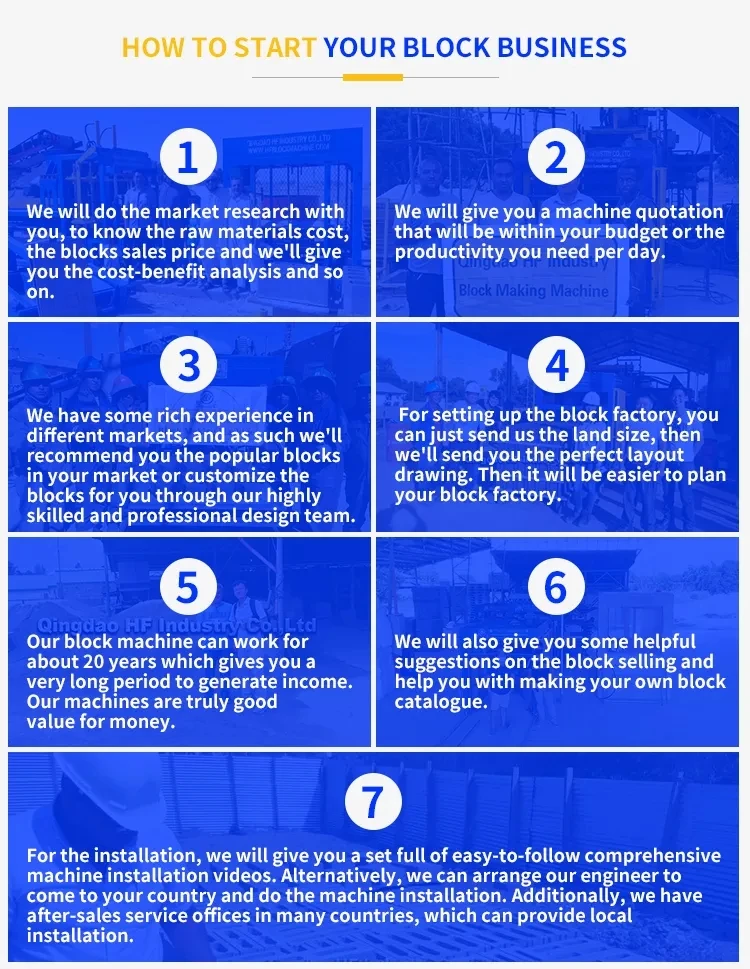

Our service

Inquiry service:

Accept user’s enquiries by all kinds of ways and establish user’s product cognition.Provide all kinds of product data and let customer understand characteristics of this hydraulic concrete block machine.

Pre-sale service:

Accept inquiry of customers ,/confirm/iation of investment advice of choice of product ,assist the customers to design the workshop

In-sale service:

Sale of product,help customers build the base ,technical training of customers’ workers ,practice of operation ,help to install ,train the operators in the workshop.

After-sale service:

24 hours service of technology inquiry, instant components supply, regularly technical service guidance of maintain,long distance malfunction control.

Unique service:

System upgrade,special design according to the customers’ requirement, mould renew ,supply new technology and automatic brick making machine information.