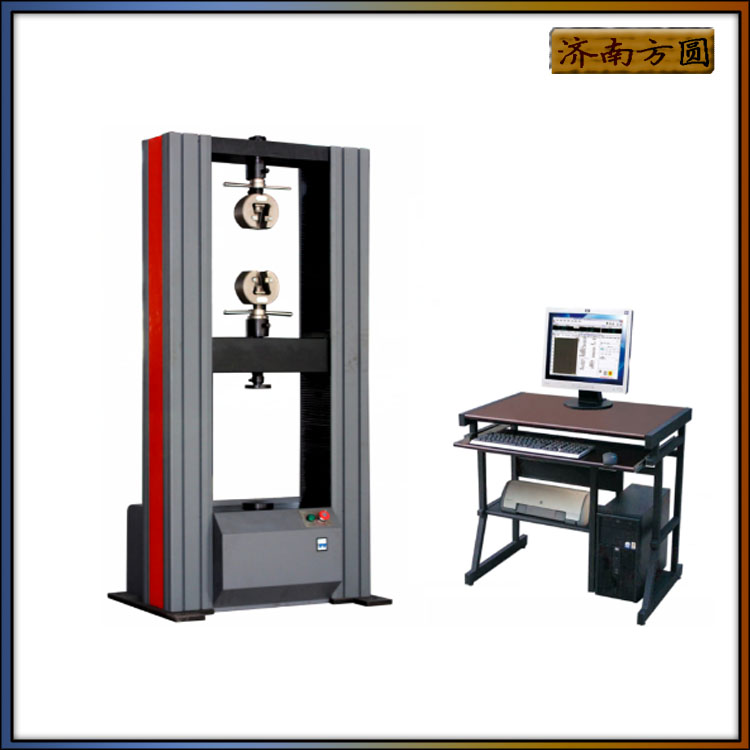

100KN Scaffold Fastener Universal Testing Machine Product Introduction

Contact us

Jinan Fangyuan Testing Machine CO.,Ltd

TEL:13864006141

Email:jnfysyj01@163.com

Wechat:13864006141

Address:No.276,Nanxinzhuang West Road,Shizhong Dist.,Jinan, Shandong, China.

Website:www.shijinyiqi.com

Technical parameter

1. Equipment model WDW-100E

2. Testing machine accuracy level 0.5

3. Maximum test force (dual sensors) 100KN 5KN

4. Test force measurement range 0.4KN-100KN 0.02KN-5KN

5. The relative error of the test force indication is better than ± 0.5% of the indication value

6. Test force resolution 1/± 500000 of the maximum test force

7. The minimum reading of the test force is 0.01KN of 100KN 0.001N of 5KN

8. Deformation measurement range 0.2% -100% FS

9. The relative error of deformation indication is better than ± 0.5% of the indication value

10. Deformation resolution: 1/± 500000 of the maximum deformation amount

11. The relative error of displacement indication is better than ± 0.5% of the indication value

12. Minimum displacement reading 0.001 mm

13. Force control rate adjustment range 0.002-5% FS/S

14. Within ± 0.5% of the relative error set value of force control rate

15. Deformation rate adjustment range 0.002-5% FS/S

16. When the relative error rate of deformation control rate is<0.05% FS, it is within ± 2% of the

set value;

When the rate is ≥ 0.05% FS, it is within ± 0.5% of the set value

17. The speed adjustment range of the crossbeam is 0.001-500mm/min; (The speed within the interval can

be set arbitrarily)

18. When the relative error rate of beam speed is<0.001mm/min, within ± 1.0% of the set value; When

the speed is ≥ 0.001mm/min, within ± 0.2% of the set value

19. Constant test force control range 0.2% -100% FS

20. Constant deformation control range 0.2% -100% FS

21. Constant displacement control range 0.2% -100% FS

When the set value of constant test force control accuracy is less than 10% FS, it is within ± 0.5%

of the set value;

When the set value is ≥ 10% FS, it is within ± 0.1% of the set value

23. Constant deformation control accuracy

24. Constant displacement control accuracy

25. Effective stretching space>750 mm (supports customization)

26. Effective compressed space>750 mm (supports customization)

27. Beam movement space>1000mm (supports customization)

28. Effective test width 450 mm (supports customization)

29. Measurement device for anti slip coefficient of right angle fasteners 1 Δ 1. Use high-precision

photoelectric encoder

2、 Δ 2. Using an electronic collector

30. Torsional stiffness of right angle fasteners 1. Use a 5KN sensor for force measurement

2. Displacement measurement using electronic collectors

31. Measurement device for anti slip coefficient of rotating fasteners 1 Δ 1. Use high-precision

photoelectric encoder

2、 Δ 2. Using an electronic collector

32. Protection device (automatic shutdown) overload, overvoltage, overcurrent, limit protection

33. The overall size of the host is approximately 860 * 680 * 2320mm

34. Power supply 220V ± 10% 50HZ, 2kW

35. The weight of the host is approximately 960KG

36. Suitable for GB/T15831-2006 Steel Pipe Scaffold Fasteners

37. Test items that can be completed: Steel pipe scaffold fasteners

Tensile strength test for docking fasteners

Right angle fastener anti slip test

Right angle fastener failure resistance test

Torsional stiffness test for right angle fasteners

Anti slip test of rotating fasteners

Rotational fastener failure resistance test

base compression test

38. Optional Test Items

1. Safety net mechanical aids

2. Seat belt mechanical aids

3. Steel pipe fasteners, steel pipe tensile aids

4. Other stretching, compression, bending, and shearing aids

39. Selection of Test Standards

1. Built in hundreds of GB, industry standards, and international standards

2. New test methods can be added according to test requirements

40. Test conditions

1. Environmental temperature: 10 ° C to 35 ° C, relative humidity ≤ 80%;

2. There is no corrosive medium, strong magnetic field, or vibration around;

3. The fluctuation of power supply voltage should not exceed 10% of the rated voltage, and there

should be reliable grounding.